Product Description

Transmission shaft

Product Description

| Product Name | Transmission shaft |

| Design | Can be at the customer’ request, tailor-made, at customer’s design |

| Advantage | ZJD can provide the transmission shaft according to customers technical specifications. |

Our Advantages

Application

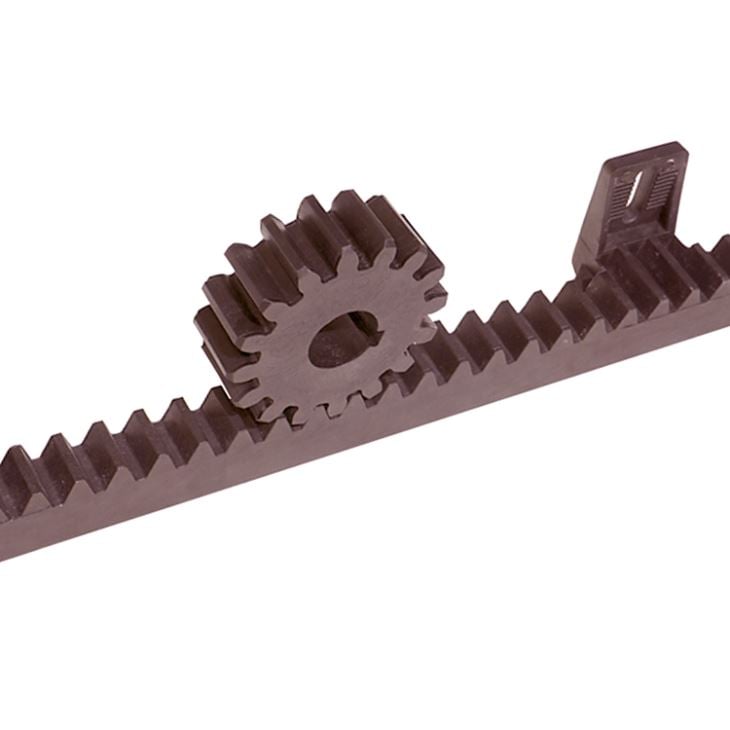

Product Display

Company Profile

ZJD is located in Xihu (West Lake) Dis. Economic Development Zone, Xihu (West Lake) Dis. District, HangZhou, ZheJiang , which has very good transportation convenience and location advantages.ZJD own 1 subsidiary, which is located in HangZhou city, ZheJiang province, which is mainly responsible for EMU accessories for CRRC’s factory nearby.

ZJD’s production and office space is more than 12,000 square meters, and more than 60 sets of various types of CNC machining and quality control equipment.ZJD’s main products are widely used in CZPT CR400, CR300, CR200 series standard EMUs, and expanded to subways, export passenger cars and EMUs and other products.

ZJD has more than 60 employees and more than 20 technical management personnel. The technical management team has many years of working experience in the rail transit industry.

Certifications

ZJD has obtained the national high-tech enterprise certification, 6 types of products have passed the high-tech certification, and related products have obtained more than 20 patents.

ZJD has established a comprehensive quality management system and has got ISO9001 quality management system certification, ISO/TS 22163 (IRIS) international railway industry standard certification, EN15085-2 railway vehicles welding system certification, and CZPT product supply service qualification certification.

FAQ

1. Who are we?

HangZhou ZJD Rail Equipment Co.,Ltd. was established in 2012, which is a professional manufacturer of rail equipment and accessories.

2. Are you a reliable supplier?

ZJD-Excellent Manufacturer focusing on the rolling stock industry

Provide full-process Design, Production, Testing and Service according to customer requirements.

3.What can you buy from us?

We have designed and supplied a series of products such an air duct systems, piping systerms, pneumatic control units,etc.The product are used in various fields such an EMUs,subways,locomotives,wagon engineering vehicles,etc.

4. What services can we provide?

Provide customized services of heavy industry products for special requirements.

Provide diversified parts and trade services such as port machinery, steel heavy industry, mining machinery, etc.

Provide customized products for new energy equipment

Provide key process technology solutions for special parts in the field of new energy equipment.

| Material: | Carbon Steel |

|---|---|

| Load: | Revolution Axis |

| Stiffness & Flexibility: | Flexible Shaft |

| Axis Shape: | Straight Shaft |

| Shaft Shape: | Real Axis |

| Appearance Shape: | Round |

| Customization: |

Available

| Customized Request |

|---|

What Is a PTO Shaft?

A PTO shaft is a component that is important for a power take-off (PTO) tractor. There are many different kinds of PTOs, including Italian, German, and North American types. The types are categorized into different series, which will have different features such as bearing diameter, cap-to-cap length, and snap rings.

Power Take-Off (PTO) shaft

A PTO shaft is a high-speed working shaft that provides torque and lift. This is an advantage for machines that lift and lower loads and are often used on construction sites. Often, the operating elements are located outside of the operator’s cabin. A safety system is also present that allows the PTO shaft to automatically disengage if it is not turned on.

A safety retaining band 12 is used to secure the PTO shaft. The retaining band extends axially from the PTO shaft S and includes a hinge. The band may be adjustable in width to ensure a correct clearance from the PTO shaft. If necessary, it may also be secured with a conventional over-center clamp.

The power-take-off (PTO) shaft is a crucial part of a tractor. Understanding how power is transferred from the tractor’s engine to the implement requires a better understanding of how this shaft works. The torque and speed of the PTO shaft is essential to developing and utilizing the power of the tractor. There are many ways to measure torque and speed at the PTO shaft, including using a telemetry or encoder system.

A Power Take-Off (PTO) shaft safety retainer is an inexpensive, dependable, and fully effective device that protects the PTO shaft from entanglement. Its effectiveness will become clear after reading the specification. A power take-off shaft safety retainer is not difficult to install and is a good choice for many applications.

PTO shafts have a dangerous tendency to separate from the driven machinery. This poses a safety hazard because the PTO shaft can continue to whip around while the operator is driving the machine. Additionally, it can be very difficult for the operator to reach the power plant when operating PTO-driven equipment.

Safety chain

The safety chain on your PTO shaft is an important component of your tractor’s safety system. A properly guarded PTO can prevent entanglement with people, tools, and objects. Moreover, it reduces the risk of the PTO shaft becoming detached from the tractor. It also prevents people from stepping over the rotating shaft.

When not guarded, a PTO shaft is extremely dangerous. It can cause serious injuries and even death. Proper safety chains can prevent this from happening and protect livestock from damage to the PTO shaft. If you’re looking to purchase a safety chain for your PTO shaft, be sure to get one that fits tightly.

When properly attached, a safety chain can keep the shaft from swinging when the PTO is engaged. A 540-rpm PTO shaft will make more than two complete revolutions in less than five seconds. That means it can wrap someone in five tenths of a second. And if you try to pull away, you’ll get wrapped even tighter!

Another reason to use a safety chain is to prevent injury from clothing getting caught in the drive shaft. A jacket or a sweater can entangle itself around the PTO shaft and cause a serious injury. The clothing can also trap the injured limb against the shaft. Hence, the chain should be removed as soon as possible after the operation is completed.

A safety chain is an essential part of your tractor’s safety system. It prevents an accident from happening because of improper maintenance. A poorly maintained PTO shaft can result in severe injuries or even death. Properly installed and maintained safety chain can help you prevent any kind of PTO shaft accident.

Universal joint

A bad universal joint can cause a number of problems for your tractor or implement. These issues may include squeaking or clunking noises when you shift gears, or a shuddering sensation when you brake. If you notice any of these symptoms, it is best to take your vehicle to a mechanic right away for a thorough inspection. If not fixed properly, a bad universal joint can separate from the drive shaft and cause major damage to the tractor or implement.

In order to choose the proper universal joint, you must consider the size of your PTO shaft. Some implements have a diameter of 14 inches or more from the hitch point to the end of the input shaft. The longer distance helps prevent the PTO shaft from bottoming out when making sharp turns. It also prevents the two parts of the shaft from detaching during cornering.

Universal joints are used in agricultural and forestry equipment and other vehicles with large number of rotors. They can be made of different materials. The most common is steel or stainless steel. This material can last for many years. A universal joint is an excellent option for small tractors, lawn mowers, and other agricultural equipment.

The universal joint is also very useful when coupling or extending drive lines. It comes with 2 yokes and a cross kit. The yokes measure 6 x 13/8″ spline, while the cross kit measures 30,2 x 92 mm. The universal joint is made to withstand extreme temperatures. It can be easily disassembled and serviced if necessary.

Square rigid shaft

Torsion is a property of a mechanical system that is affected by changes in torsional rigidity. Torsional rigidity is measured as the torque needed to twist one unit of angular measurement over one unit of length. A shaft with high torsional rigidity will provide a stable mechanical interface.

Different shafts may have different types of collars. The most basic one is a sleeve, which is composed of a thick tube with the same diameter as the shaft. The sleeve is attached to each end of the shaft and has threaded inserts to prevent longitudinal movement.

The PTO shaft also has a safety shield on both ends. It helps to prevent accidents by securing equipment to the tractor. It can be found in domestic and metric shapes. The domestic versions are generally round and domestic shaped, while metric versions are available in a bell, football, star, and metric shape.

An CZPT coupling consists of three pieces: a center plastic disc, two encompassing discs, and a flange. These parts are joined together with a ring that is screwed to the shaft. Some couplings feature oil injection points on the coupling. These can supply oil under pressure to the coupling’s annular grooves. This helps it ‘float’ and aids in the removal.

Another type of flexible coupling is the universal joint. These couplings can be made from a variety of materials, such as rubber, braided metal wire, or woven wire. They can be fabricated to withstand various misalignments. But, unlike rigid couplings, flexible couplings are susceptible to shock and vibration.

Economy PTO

Economy PTO shafts are designed to reduce the overall torque and power consumption of a tractor. They can be manually adjusted to engage and disengage the PTO. The cab mounted control/monitoring unit 14 has a switch 19 that selects between the economy and normal driving modes of the PTO. Using the economy mode decreases the engine rpm while using a lower gear ratio to drive the PTO shaft.

Economy PTO shafts come in hydraulic and mechanical versions. Both types are suitable for agricultural tractors. They allow the tractor to operate at a lower rpm, which reduces noise and vibration. They can also be used in a wide range of equipment. The transmission PTO is the oldest type, and is directly connected to the transmission. When the clutch is engaged, it drives the transmission.

Standard PTO shafts are available in various diameters, splines, and speeds. Many implements are designed to be compatible with one or more of these types of PTO shafts. The domestic versions come with a splined front shaft and a square, rectangle, or round secondary shaft.

Another difference between the two types is the number of teeth on the toothed wheel. The economy PTO allows the tractor to run at a lower rpm than the standard PTO. The engine rpm can go as low as 1600 while using the economy PTO. It also helps to reduce noise and vibration in the cab.

The present invention solves these issues and provides an increased level of automation and operator awareness of the PTO function. It also includes a system for detecting the type of PTO shaft and automatically setting the parameters of the control routine.

editor by CX 2023-10-25

OEM Cheap made in China – replacement parts – in Bucharest Romania Factory High Precision Steel Motor Gear Shaft with Spline with top quality

We – EPG Team the bigge EPT gearbox & motors , vee pulleys, timing pulleys, couplings and gears manufacturing facility in China with 5 various branches. For far more specifics: Cell/whatsapp/telegram/Kakao us at: 0086~13083988828 13858117778 0571 88828

HangZhou Xihu (We EPT Lake) Dis.g EPT EPT Co., Ltd. was started in 1980. We are specialised in precision areas and components machining, which are used in electronics, automotive parts, astronautical parts, health care appliances and hand resource industries. We give a range of design and producing which includes customized CNC machining, CNC machined areas, non-normal machine areas, machined casting Components and precision turned elements. The materia EPT of hardware elements incorporate metal, stainless metal, brass, aluminum and plastic. If you are intrigued in any of our goods, please feel totally free to get in touch with us. We are looking forward to the cooperation with you, and we think that we will be your excellent decision.

Main Items

Our business focus in making all kinds of inner and external gear,higher precision dress in-resistant worm wheel,worm,internal and outer spline.

1. Gear

2. Shaft & Axle

3. Shaft Coupling

four. Pulley

five. Sprocket

six. Flange

| Part name | Shaft |

| Materials Available | one. Stainless Steel: SS304 , SS316,SS420 |

| two. Carbon Steel:C45(K1045), C46(K1046) | |

| 3. Brass: C37700 ( HPb59) | |

| 4. Bronze: C51000, C52100, C54400, etc | |

| five. Iron: 1213, 1214,1215 | |

| 6. Aluminum: 6063 T5 6063T6 6061 T5/T6, 7075 T5 /T6 | |

| Used | Mining Industry, Electrical power Plant, Port, Pump, Admirer, Electricity transmission |

| Surface Treatment | High frequency treatment ,Hardness teeth, integral heat treatment, blackening, Zinc-plated, Nickel-plated, anodized etc. |

| Processing Method | CNC machining, Shaving m, Hobbing grinding, chamfering etc. |

| Dimensions | Customer Drawings & ISO standard |

| Deal | Plastic Bags and Wooden Cases |

| Certification | IATF 16949:2016 |

| Benefit | Assured quality , Best services, Competitive prices, Fast delivery |

| Lead Time | five-ten Times for Samples20-35 Times for Batch Goods |

Company Honor

Create a considerably effecitive route of brand institution to mack the develoment of our enterprise far more standardized and in depth.It is top quality,details,carefulness and perisistence that mack the brand much more aliveand it is standards,responsibilities,honors and missions that encorage us to inherit the pa EPT and produce the foreseeable future.

Manufacturing Products

The sucess of Yingxing not only relies on the perfection on the area,but a lot more on the delicacy of each and every and each and every depth.We have innovative contemporary gear and powerful technological strength,which guarantees us to manufacture approximate ideal items.

Good quality Control

Our company has a single of the mo EPT stringent top quality control systems,from our feed testingand product inspection to the ultimate inspection method.Rigorous top quality procedure management and administration ensurus merchandise top quality and accountabilty.

Generation Approach

Packaging & Transport

Our provider

one. Prompt reply to your enquiry and swift quotations within 24 hrs.

two. Check out your gears drawings extremely carefully and feedbacks with professional engineering concerns on your types.

3. All gears dimensions and tolerances will meet your drawings and take away all risks soon after your POs.

four. Punctual lead time and send out you samples ahead of bulk creation.

five. Accountable for all defects or reduction from the gears we developed.

FAQ

Q1:How to assure the Top quality of Industrial Components?

A1:we are IATF 16949:2016 certified firm.In 2004, we passed the ISO 9001:2000 high quality system certification.In 2571,we passed the ISO 9001:2008 Good quality Technique Certification of China Classification Modern society.we have the integrated method for industrial elements quality manage. We have IQC (incoming quality control), IPQ EPT (in method quality handle segment), FQC (last high quality manage) and OQC (out-heading high quality management) to handle every single process of industrial areas prodution.

Q2:What’s the Benefit of Your Elements for Business Items?

A2:Our gain is the competitive charges, fa EPT delivery and higher high quality. Our workers are responsible-oriented, helpful-oriented,and dilient-oriented. our Industrial parts merchandise are highlighted by rigid tolerance, smooth finish and extended-life overall performance.

Q3:what are our machining equipmengts?

A3:Our machining equipments incorporate CNC milling machines, CNC turning equipment, stamping machines,hobbing machines, computerized lathe devices, tapping equipment, grinding equipment,screw machines, slicing equipment and so on.

This autumn: What shipping techniques our use?

A4:Usually talking, we will use UPS or D EPT to ship the goods. Our buyers can attain the merchandise in 3 days.If our clients do not need them urgently, we will also use Fedex and TNT. If the products are of heavy weight and huge volumn, we will ship them by sea.This way can help save our buyers a good deal of cash.

Q5:What materia EPT can you manage?

A5:Brass,bronze,copper,stainless steel, steel,aluminum and titanium.

We – EPG Team the bigge EPT gearbox & motors , vee pulleys, timing pulleys, couplings and gears manufacturing facility in China with 5 various branches. For a lot more specifics: Cellular/whatsapp/telegram/Kakao us at: 0086~13083988828 13858117778 0571 88828 The use of original equipment manufacturer’s (OEM) part figures or trademarks , e.g. CASE® and John Deere® are for reference needs only and for indicating merchandise use and compatibility. Our company and the detailed substitution parts contained herein are not sponsored, accepted, or manufactured by the OEM.

Best China manufacturer & factory factory in Sukkur Pakistan manufacturer for custom high precision forged machining metal driving spur bevel gear spline shaft With high quality best price

The new products include a series of high-tech and high quality chains and sprockets and gears, such as chains and gearboxes for agricultural machineries, metallurgical chains, escalator step-chains, high-speed tooth chains, timing chains, self-lubrication chains, among which have type high speed tooth chain for car branch dynamic box and aerial chains fill in the blanks of chain in China.

Overview

Quick Details

- Applicable Industries:

-

Manufacturing Plant

- Local Service Location:

-

None

- Surface Treatment:

-

Blacking, Polishing, AnoSingle direction FREE WHEEL (RA) Single direction PAWL torque limiter (SW) Disc torque limiter clutch with spring (FFT)dization, Chrome Plating, Zinc Plating

- Heat treatment:

-

Quenching & Tempering, Carburizing & Quenching

- Standard:

-

DIN, ISO/GB, AGMA, JIS,ISO/TS16949:2009

- Year:

-

2014-2016, 2014-2015, 2010-2016ear:

- Tolerance:

-

Based on drawing Length Dimension

- Specification:

-

According to the the drawing

- model:

-

CT660, X-BOW

Supply Ability

- Supply Ability:

- 5000 Piece/Pieces per Month

Packaging & Delivery

- Packaging Details

- Neutral paper packaging, wooden boxes for outer box or according to customer’s demand.

- Port

- Shanghai / Ningbo

The shaft surface under the oil seal lip is critical to effective sealing. Any lead remaining from the turning process acts like an oil pump and causes leaks. While plunge grinding is the most common method for finishing seal journals, the process does not guarantee acceptable surfaces.

-

Lead Time

: -

Quantity(Pieces) “EPG” brand rotocultivator ploughshares in T.S. total lines produced in our factory have been tested and appraised by the Ministry of Agriculture and have obtained the license of popularizing farm machinery promulgated by the Ministry of Agriculture of the People’s Republic of China.

1 – 1000 >1000 Est. Time(days) 15 To be negotiated

Online Customization

We Ever-Power Group with 4 branches over 1200 workers is one of the biggest transmission parts and machining items manufacturers in China

Product Description

custom high precision forged machining metal driving spur bevel gear spline shaft

(1). All kinds of gears, shaft, gear shaft, precision gear and CNC gear.

(2). Specialized in manufacturing all kinds of automobile transmission part based on drawings

(3). Material: ductile cast iron, carbon steel, alloy steel , stainless steel, , bronze/brass

(4). Modules: M1 to M8

(5). Meets ISO, DIN and ASTM standards

(6). Specification : According to the the drawing

|

Material |

Carbon Steel |

SAE1020, SAE1045, Cr12, 40Cr, Y15Pb, 1214Letc |

|

Alloy Steel |

20CrMnTi, 16MnCr5, 20CrMnMo, 41CrMo, 17CrNiMo5etc |

|

|

Brass/Bronze |

HPb59-1, H70, CuZn39Pb2, CuZn40Pb2, C38000, CuZn40etc |

|

|

Tolerance Control |

Outer Diameter |

Based on drawing |

|

Length Dimension |

Based on drawing |

|

|

Machining Process |

Gear Hobbing, Gear Milling, Gear Shaping, Gear Broaching, Gear Shaving, Gear Grinding and Gear Lapping |

|

|

Teeth Accuracy |

DIN Class 4, ISO/GB Class 4, AGMA Class 13, JIS Class 0 |

|

|

Modules |

1.0, 1.25, 1.5, 1.75, 2.0, 2.25, 2.5….8.0 etc |

|

|

Heat Treatment |

Quenching & Tempering, Carburizing & Quenching, High-frequency Hardening, Carbonitriding |

|

|

Surface Treatment |

Blacking, Polishing, Anodization, Chrome Plating, Zinc Plating, Nickel Plating |

|

|

Standard |

1. DIN, ISO/GB, AGMA, JIS,ISO/TS16949:2009 |

|

Packaging & Shipping